2021-2023 Repairs:

Apache 37 Rudder, Anchor Windlass, Cabin Top

Fuel Polishing

and Diesel Tank Cleaning

Rudder Repair

In 2021 my buddy Dave and

I were sailing to Maine, when he noticed that there was a tiny bit

of play in the tiller. The rudder and tiller have always been

super tight. Now it had maybe 1/4" to 1/2" of motion at the end of

the 3' tiller, certainly not much. I checked the tiller, tiller

hinge, and top rudder bearing and they were all fine. But on

a 53 year-old rudder, play in the rudder itself could be bad. I

didn't know exactly how the rudder was constructed internally, but

I suspected stainless plates, welded to the rudder stock (shaft).

Then surrounded by wood. Is the wood badly rotten? Worse, if there

are lets say 3 plates welded to the shaft, maybe 2 of the welded

plates had broken loose? Time to investigate.

First step: Where is the

play?

There is less than 1/8" of

the rudder shaft visible above the rudder when it is mounted to

the boat. I wanted to get a large pliers on the shaft. I dropped

the rudder about 3/4", enough to get a vise-grip on the shaft, and

sure enough, the play was between the shaft and the rudder. Not

good.

Second: Remove rudder and

bring it home. Easy enough. I removed the rudder in the fall so I

could troubleshoot it properly over the winter.

Third: I got a small metal

detector. The metal detector showed thin metal parts fore-and-aft,

about 1/4 and 1/2 way from the top. It showed one larger

metal area near the bottom. I drilled 1/4" holes. The 'rods' were

about 1/2" wide, in the center of the rudder (about 1" deep) and

the plate was very close to the surface. It was close to the

surface on both sides. Strange, definitely not conventional rudder

construction. The core is solid mahogany. The wood was in good

condition. A bit of moisture, but all solid.

With a grinder, a chisel,

and reciprocating tool I opened up the areas around the joints

between the shaft and the rods, and between the shaft and the

plate.

The rods are 3/8"

and go through holes in the 1.5" shaft. The ends of the rods are

peened over to keep them from moving. The bottom plate is maybe

3/16: stainless or Monel, and is bent (wrapped) around the the

shaft. All of these had a bit of play. Apparently the rods or

holes in the shaft have worn and loosened up a bit over 53 years

of sailing.

The good news is that the

play probably wouldn't get too much worse and should not fail

catastrophically. The bad news is that it will gradually get a bit

worse over time, and all the rudder torque depends on these 2

rods. The shaft is constantly moving in the rudder, making it

almost impossible to keep water out of where the shaft enters the

rudder, top and bottom. This could help explain some of the winter

cracking that I have experienced the past 7 or so years. After

thinking about it for a while, I decided to have the rods and

plate welded to the shaft, and to add some small stainless gussets

welded on to strengthen the joints on both sides. This worked very

well. My thanks to Lawton welding in Topsfield, MA. They do

stainless welding very well.

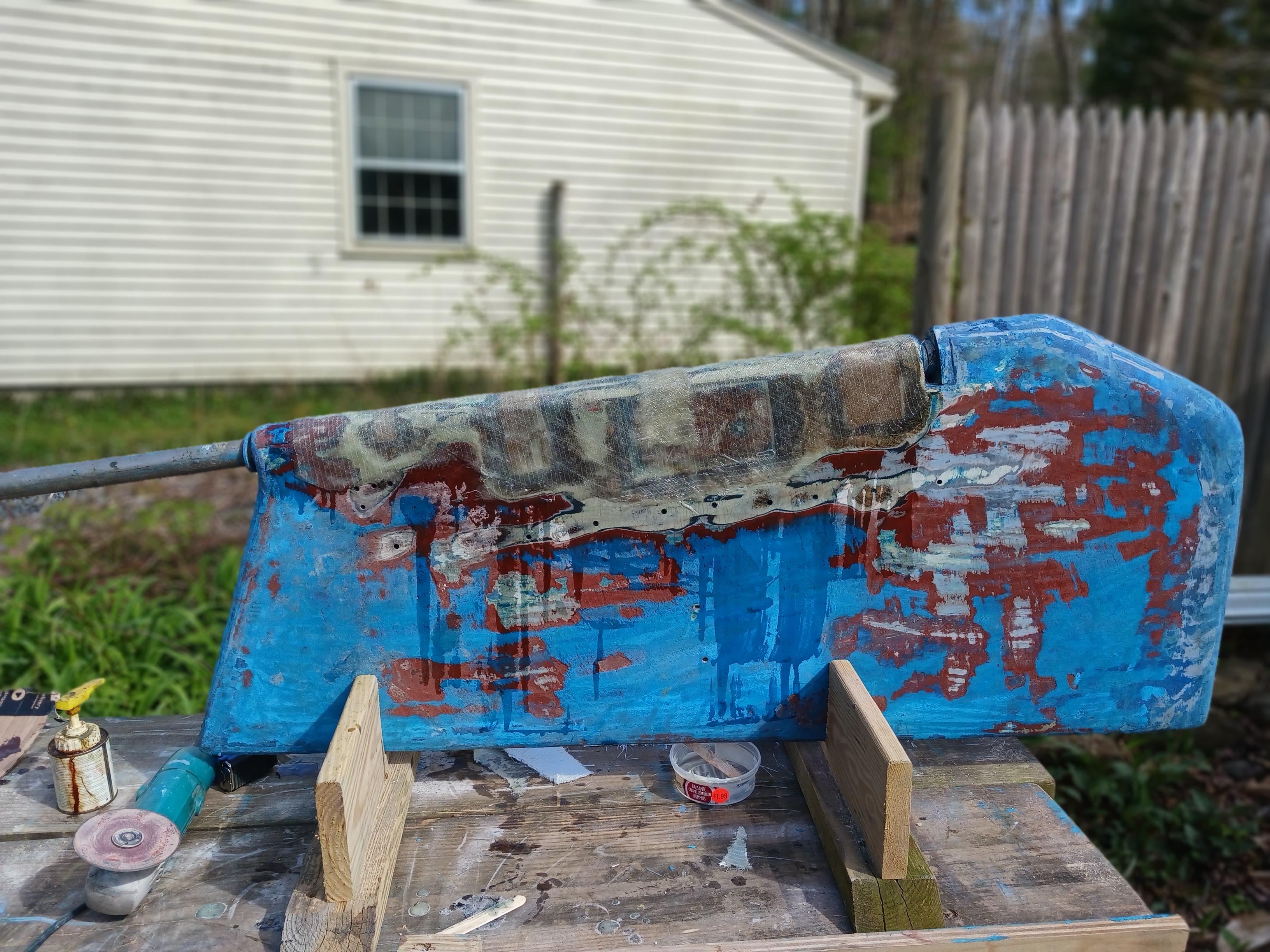

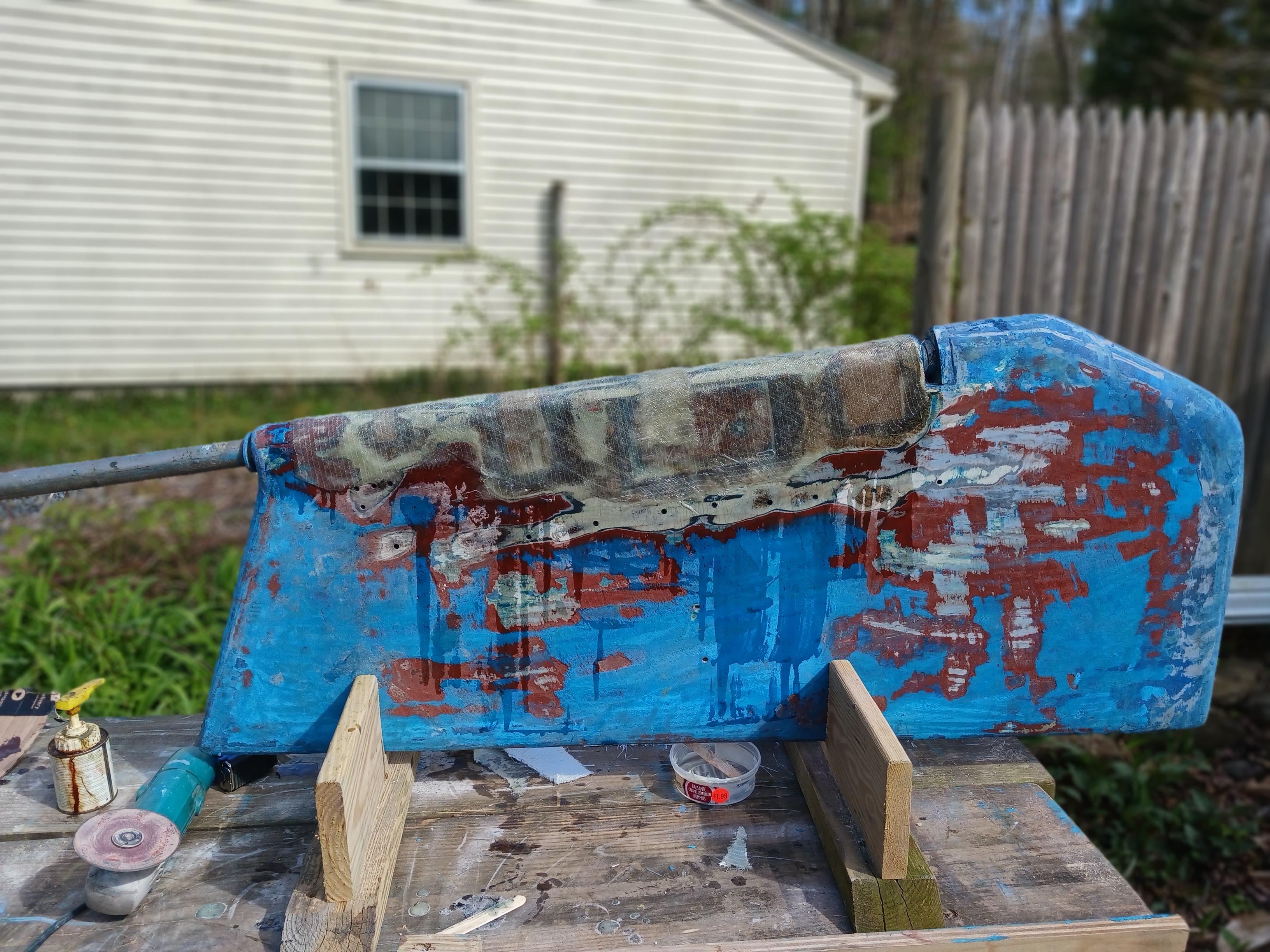

Here is the process of glassing up the holes. I filled the larger

voids with chunks of foam core, ground the area down, then added

2-3 layers of biaxial stitch mat (1708).

Faired everything, added 3

layers of barrier coat, and installed it. The top of the rudder is

very close to the skeg, like 1/16".

BTW, here is a disturbing image of a more 'standard' Apache 37

rudder that failed in 2021. You can see the 3 plates that I

expected, with the bottom one broken off, and the resulting rudder

gone.

Cabin top sides Delam

I had patched up and

painted the port cabin side to repair a few feet of delam, maybe

2-3 inches wide, just

under the opening ports. I painted the cabin sides over the repair. 15 years

later, it was apparent that my patch wasn't holding. There were

cracks and blisters in a strip almost 10' long. Also the two large

ports were leaking, so this would be a good time to remove and

rebed them.

In the fall of 2021, we hauled early, in mid-September, for a

hurricane that never happened. I took advantage of the nice autumn

weather to do this long-awaited project. I stripped the 15 year old

paint, removed the two large ports, glassed the gap between the outer skin and the

headliner, and ground down about a 10' strip where

the delam was. I added some glass, ground and faired it, and tried

to match the gel-coat color. I don't have good before and after photos, just this

one 'after' example of poor color matched gel-coat. The two ports

are the large ones. Not sure why the photo is upside-down.

The reapair went well. Gelcoat color match is still not perfect,

but at least it is smooth, structurally sound and weatherproof.

The starboard side needs a similar repair, but much smaller.

2020 New Roller Furler

My roller furler was an

ancient Cruising Design continuous line unit. It used an internal

wire halyard and required a temporary halyard to be fitted to

raise or lower the sail. It was not convenient to change sails,

and so we rarely did it. One of the extrusions had some serious

longitudinal cracks, and the furling line regularly jumped the

drum. It was time.

My original small jib was original 1968 vintage. It had been

damaged and I rarely used it. I tried to get a new small jib made

in 2017, but my favorite sailmaker was too busy. So I took the

measurements to Ebay, and found a great North Genoa from a 35'-ish

boat. The UV cover was my color, Captains Navy, and it had the

perfect sail number: 42! The price was right at $500. We put it

on, thinking we would use our 135% when the wind was light. That

was 5 years ago and we have never changed it once. As we get older

and are more conservative sailors, being underpowered is more

desirable than being overpowered. I single-hand a fair amount too.

Whenever the thought enters my mind "Maybe we should change to the

big jib" the wind picks up shortly after. We love our small jib.

We almost never need to reef the jib.

We looked at Harken

furlers, and finally were convinced by Kevin at Northeast

Rigging to use the smaller (Size 1, up to 36') racing version

(MKIV). Going smaller saved $ and weight, and considering that

we regularly use a small jib and so rarely reef, it has worked

very well.

2022 Anchor Windlass

As I age, hoisting our 35#

anchor and 45' chain also gets old. We purchased a new Maxwell

Windlass and installed it on our Summer 2022 Maine Trip. Happy,

Happy, Joy, Joy.

I use a teak fairing block to raise the windlass up a bit since

the chain needs to go up over the bullwark which is nearly 6"

high. The vertical angle is limited to about +/- 6 degrees.

Here is the rope to chain splice in process.

Inside the chain locker. I had some problems with the rope binding

when raising anchor. Originally I thought it was that the chain

drop wasn't enough: it needs to be 12". I removed the windlass and

examined the hole. I use a riser block and the holes in the riser

block and the deck didn't line up perfectly, so the rope was

sticking on the block. I enlarged the block hole to line up with

the deck hole, smoothed the holes, and all is well.

And the anchor. I needed to swap the plow from port to starboard

since the windlass chain is on the starboard side.

2023 Bottom Stripping

I have been wanting to

strip the bottom for years. The old bottom paint is thick and

hard, and sometimes comes off in chunks. The bottom is not smooth.

I tried a few times to strip parts of the bottom. I tried

scraping, sanding, and chemical strippers. It is a messy and

back-breaking job. In addition my boat yard discourages bottom

stripping. I do very small areas and keep the mess cleaned up at

all times.

I saw some reviews, and decided to try a small area of stripper

called Peel-Away

last Fall using their gallon size. It only did about 20 sq ft.

I bought a 5 gallon pail of it ($180) and did the aft, port

quarter this past spring. It easily removed the top layers.

I tried a second application and it helped, but the old hard

bottom paint is really tough. Instead I scraped it with a

two-handed carbide scraper. Tough work, I did a bit at a time.

Eventually I built up my upper-body muscles and we able to do

15-30 minutes of scraping at a time. I did a bit each day until it

was all down to bare gelcoat. Then a final sanding and applied 3

layers of Interlux 2000 barrier coat.

I figure I'll do 1/4 of the hull each year. About 1/5 of it was

already done.

These long scrape marks are not mine, they were there under the

red paint.

You can see some of the red paint here. The stripper took off many

layers of blue, but the red needed to be scraped.

After sanding and a couple of coats of Interlux barrier coat.

Ahhhhh.

2023 Fuel Polishing,

Tank Cleaning

After launching in May

2023, we were motoring to the mooring for the first time of the

season. The engine slowed and died, acting like fuel lines or

filter was plugged. The sight glass on the bottom of the Racor

didn't look too bad. I have a vacuum gauge to tell me when the

filter is clogged, and it read 0 as it always does meaning no

clog. I replaced the filter element and found a bunch of crud in

the filter housing. I checked the vacuum gauge and it was broken,

stuck at 0! A few days later we went for the first sail of the

season. We motored away from the mooring just fine, sailed

for 2 hours, then started the engine to motor back to the mooring.

The engine slowed and died. We sailed back to the mooring. Sailing

had stirred up the tank and plugged the fuel line. .

This identical scenario had occurred in 2014, 9 years ago. At the

time I built a simple fuel cleaning system using a small electric

fuel pump and some cheap plastic fuel filters. The Racor housing

and the fuel lines were badly plugged with diesel bug. I cleaned

the filter, lines and the tank. No problem since then.

I fired up the old electric fuel pump and it did not work. I

contacted a local fuel polisher, but the logistics didn't work. He

needed me to be at a dock with AC power, but the docks he

suggested were unavailable. And I may have had to tow the boat to

the dock. Time to DIY it again, and do it right this time. And

time to be more preventative about this problem in the future.

I bought another cheap ($80) auto-parts-store fuel pump and some

small filters. These filters quickly plugged so I had to

back-flush them several times. But they got most of the major

crud.

Also access to my tank is difficult as the fuel gauge port is

about 8" under the cockpit. I could only access it while lying in

the starboard quarter-berth. Last time, I think I drained

most of the tank, removed all the fittings, loosened the straps,

and and tilted the circular tank to starboard about 30 degrees, to

make accessing the port easier. Ugh. This time I cut a 6" hole in

the cockpit sole just above the tank. I made a simple 1/8"

aluminum cover. This made accessing the tank so much easier.

I investigated better fuel pumps and filters, and found what I

think is an ideal combination. The small parts-store or Amazon

electric fuel pumps are low capacity and don't prime well. The

ones intended for fuel transfer are high capacity (10 gal / min)

and can overwhelm a filter. Tractor Supply has pumps made by

Remco, Fimco and others, and intended for chemical spraying

including oil based fertilizers. They are about 2-4 gal / min and

about $100. I bought the Remco

3300 and it worked very well.

For a filter, you need a large one to handle 2 gal/min. I found a

Racor

900 Chinese clone on Amazon for just $52. Perfect! 30 micron

filter elements are about $13. Not sure I would use a cheap clone

filter permanently on my boat, but for this once-a-year

fuel-polishing job, it seemed ideal. I used 3/8" flexible sprayer

hose, also from Tractor Supply. Worked well.

I mounted the pump, filter, and a switch to some scrap plywood,

and use a 3/8" OD bend-able copper tube in the tank. It reaches

all the nooks and crannies. I used an inspection camera to inspect

the dry parts of the tank to check for diesel bug.

Here is the 6" hole I cut in the cockpit sole. Got to love that

Apache 37 foam-core deck layup. I plan to recess the aluminum

cover a bit. Spring boatyard project.

So if you have an old boat with an old diesel tank, here are my

recommendations:

- Build

a fuel polishing / tank cleaning system (<$200)

- Make

the tank easy to access

- Clean

the tank and polish the fuel in the spring, every year or two

- Fill

the tank before winter storage to reduce condensation. (I

usually had 1/2-3/4 tank, never full.)

- Use

a good fuel treatment religiously, including jerry cans. (I

was not very religious. I am now.)

Here is

the crud that this tank cleaning session dredged up, about 12oz

in a 24oz jar.Pretty nasty.