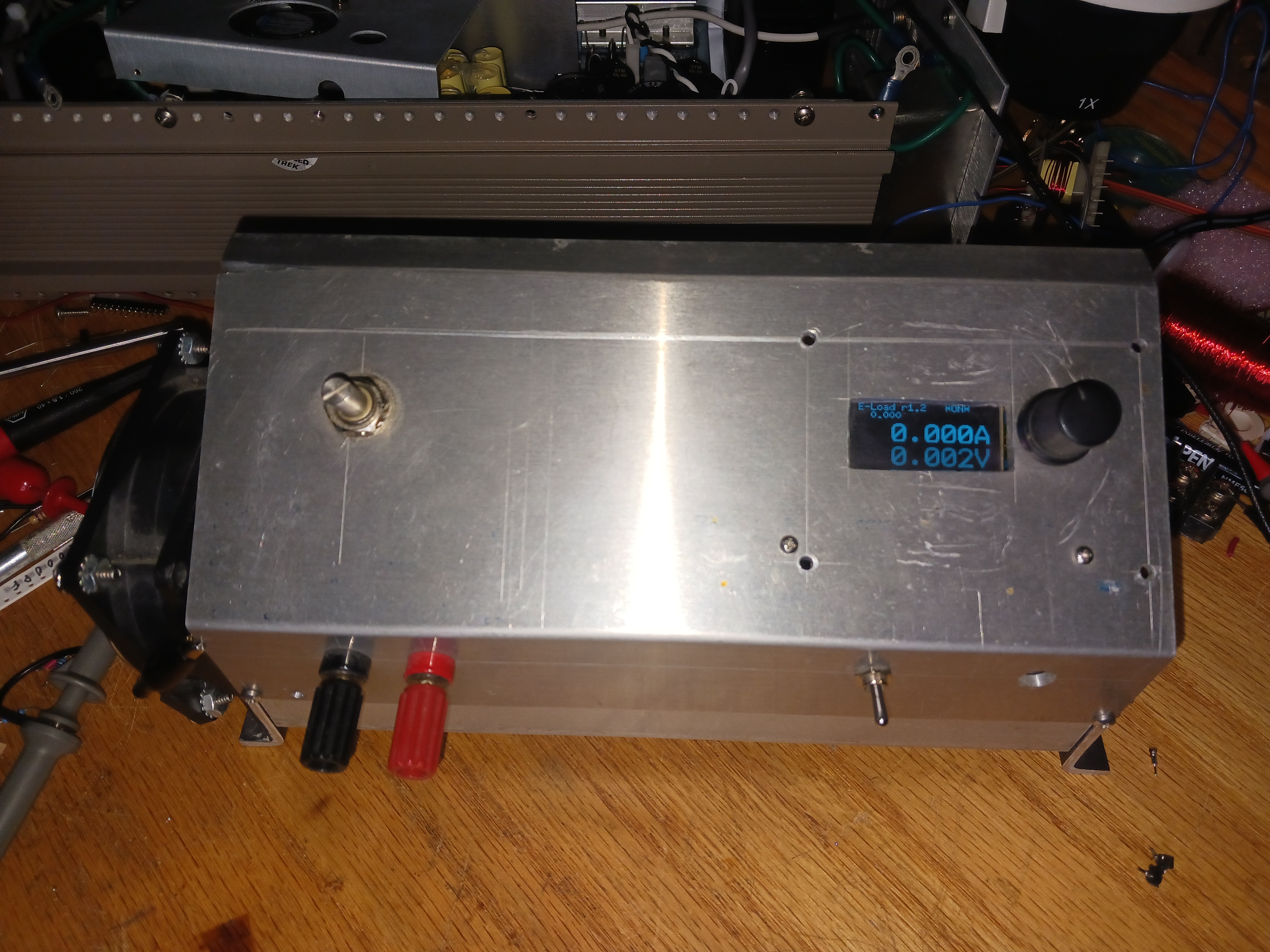

E-Load Electronic load. The project that will not end....

Adjustable DC Load

To test power supplies, a load of some kind is needed. This can be

as simple as a handful of different value power resistors. The gold

anodized power resistors made by Dale and others work great. These

can be screwed to an aluminum plate or other heat sink to keep their

temperatures low. I keep some 1.0, 5.0 and 10.0 ohm, 10W and 25W

values around. Put enough of these in series and parallel and you

can load down a power supply. But I never have the exact right

values and changing the load usually involved soldering. So I built

an electronic load. This load applies a constant current to a power

supply of between 3V and 30V. My original one used a simple power

N-FET bolted to a big heat sink, an op-amp, shunt resistor and

voltage reference. It was self powered from 20V down to about 5V and

designed for up to 4A loads. Over the years it was upgraded to 10A

and then 20A. Now I use a surplus IGBT which will dissipate 10A at

12V or more (120W) with impunity. I think it's rated to switch 75A

at 400V. At 120W or more, a fan is a must. The basic circuit is

quite simple. Build the electronics on a little Radio-Shack or other

proto-board and mount it on the biggest heat sink in your junk

drawer.

Rev 1

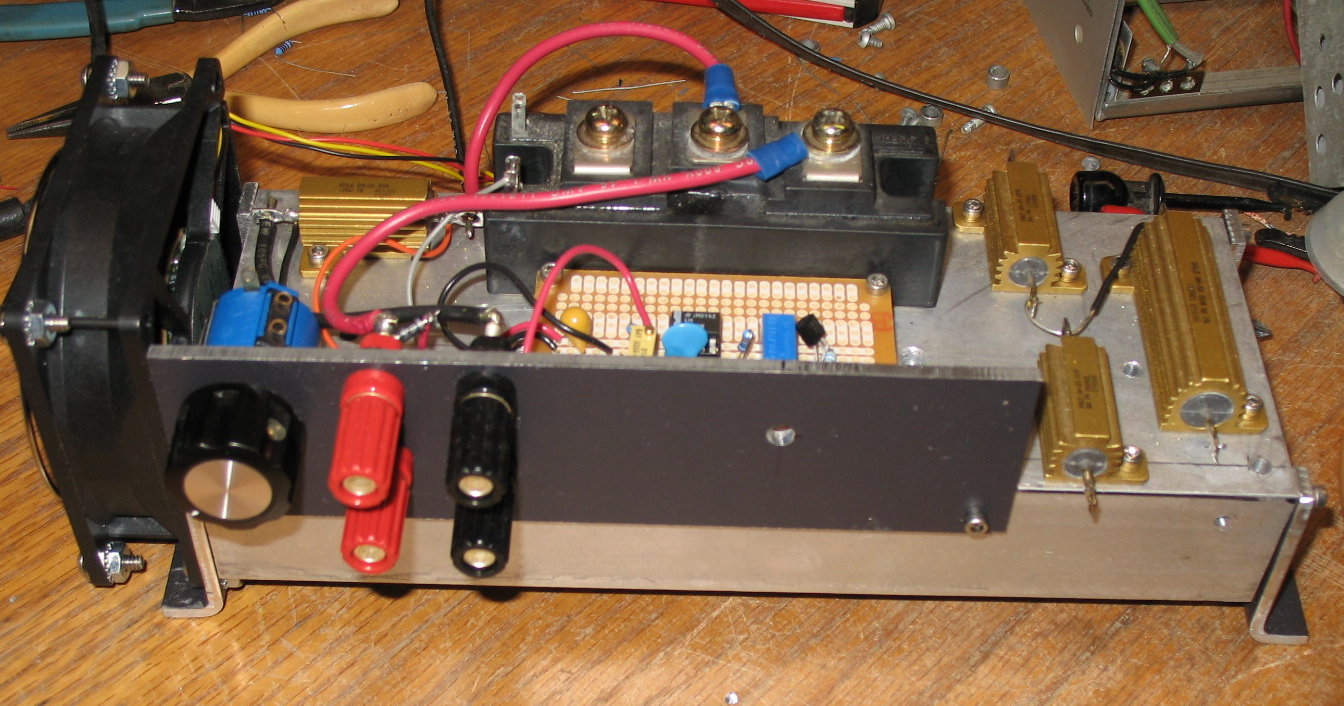

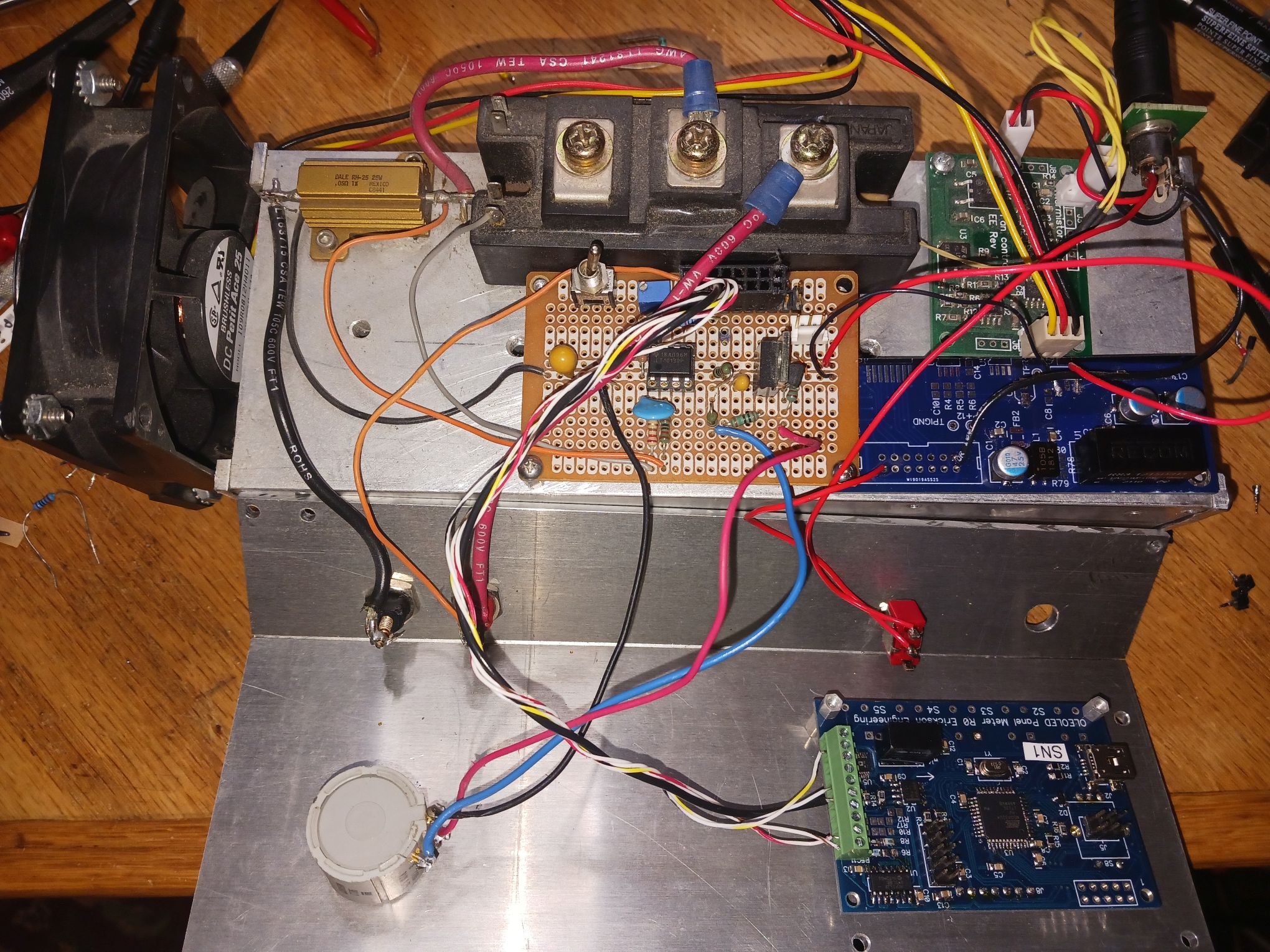

The original big heat sink (8.5 x 3.2 x 1.2") and IGBT were pulled

out of a scrap bin at Analogic in 2001. Once I had these prizes, I

had to build an E-Load Here is the original circuit. The 1.25V

reference diode, 15K resistor, and ten-turn 10K pot develop a stable

0 to 0.5V. The single-supply op-amp and FET apply the voltage to the

0.05 ohm resistor. 0.5V across 0.05 ohms is 10A maximum. You can

parallel multiple larger resistor values if you have trouble finding

a 0.05 ohm 10W resistor. To build a 5A load, use a 0.1 ohm, 5W

resistor instead. The only trick in building this is to wire the

high current path with heavy gauge (16GA or more) wire and treat the

0.05 ohm resistor as a 4-wire device: heavy traces for the high

current path, lighter wires soldered to the leads near the body for

the voltage measure path. Here is the ExpressPCB

schematic. and the .PDF.

version. For extra credit, use the unused op-amp and a

thermistor to detect when the heat sink gets hot and turn the fan

on. The circuit as shown shouldn't be used at more than 18V or so

since the full supply can be applied to the FET gate, These are

usually rated for 20V max. By removing D3 and always using the

external 12V supply, this limitation is removed and the voltage can

go up to anything the FET can handle. Watch out for maximum power of

the FET though. And remember to de-rate the FET power at high

temperatures.

The original proto had a 10K trimpot on board with an adjustment

hole in the front. Soon it was upgraded to a nice front-panel

ten-turn10K pot.

The top binding posts are for the load and the bottom ones for a

current monitor via a DMM. The 3 resistors on the right are just

spares. Note the big black IGBT in the background, this is in place

of the FET in the schematic, but a couple of high power TO-247 or

larger N-FETs in parallel will do fine. the IGBT is a half-bridge

type, with only the lower transistor used. The big aluminum

block is a surplus heat sink with its fins facing down. The steel

brackets on the end keep it somewhat thermally isolated from the

bench. I have run this beast at 24V and 10A: 240W for short periods

of time.

Here are the original specs / requirements for this version.

- Self powered or powered from the load.

- 3.0 to 30V, limited by the op-amp power supply

- 0 to 10A using a 0.05 ohm, 25W shunt resistor

- Ten-turn pot

- Use what parts I have laying around, purchase nothing!

- 100W comfortably, 200W for short periods.

- Use a big the heat sink as the chassis

- Beefy transistors or IGBT

- 12V Fan

- Uses external DMM to monitor current: 10mV/Amp

The original reason for self powering was so I could easily test 12V

batteries in the field. But a proper battery tester requires that

the load shut off below a set voltage. It also needs to keep track

of the time, in order to measure the battery Amp-hour capacity.

Also, the fan operates from the same supply, so causes ~100mA of

parasitic and un-measured current. Also a fan prefers a fixed

voltage, not some arbitrary one. Additionally, the FET really wants

about 12V-15 max, not 24V or more from the opamp. I soon decided

that self-powered wasn't such a good idea.

FET and IGBT SOA limitations in E-Loads

The power semiconductor manufacturers have recently changed how

they specify Safe Operating Area (SOA) for FETs and IGBTs. These

devices are primarily intended for switching applications, not to

dissipate hundreds of watts of continuous DC. So many parts now

only specify SOA at 10mS duration or less. Supposedly FETs can

develop hot-spots and then fail.

The part I use is an older, half-bridge IGBT module, Toshiba

MG100J2YS50. It specifies SOA up to 300W dissipation at DC,

30V @10A. 100V @2A. This thing is truly a beast.I wouldn't run it

much higher than 200W.

Back in the good old days when I first built this, FETs and IGBTs

specified their SOA at DC. Nowadays you need to buy specific

"Linear FETs" to get DC SOA curves. But for a one-off, as

long as you keep power down.... A good Linear L2 FET for a

big DC load is the IXYS

IXTN110N20 in the

beefy SOT227 package.

Another nice part I have used for high current loads is

IXFH180N20, in a TO-247, This part can handle about 150-200W

DC, but be very careful about using any thermal pads. at

150-200W, the temp rise of even the lowest thermal resistance

insulators will cause a major temperature rise. I screw them

directly to the heat sink with thermal grease, and then insulate

the entire heat sink since it is at the Drain voltage.

Inconvenient but necessary.

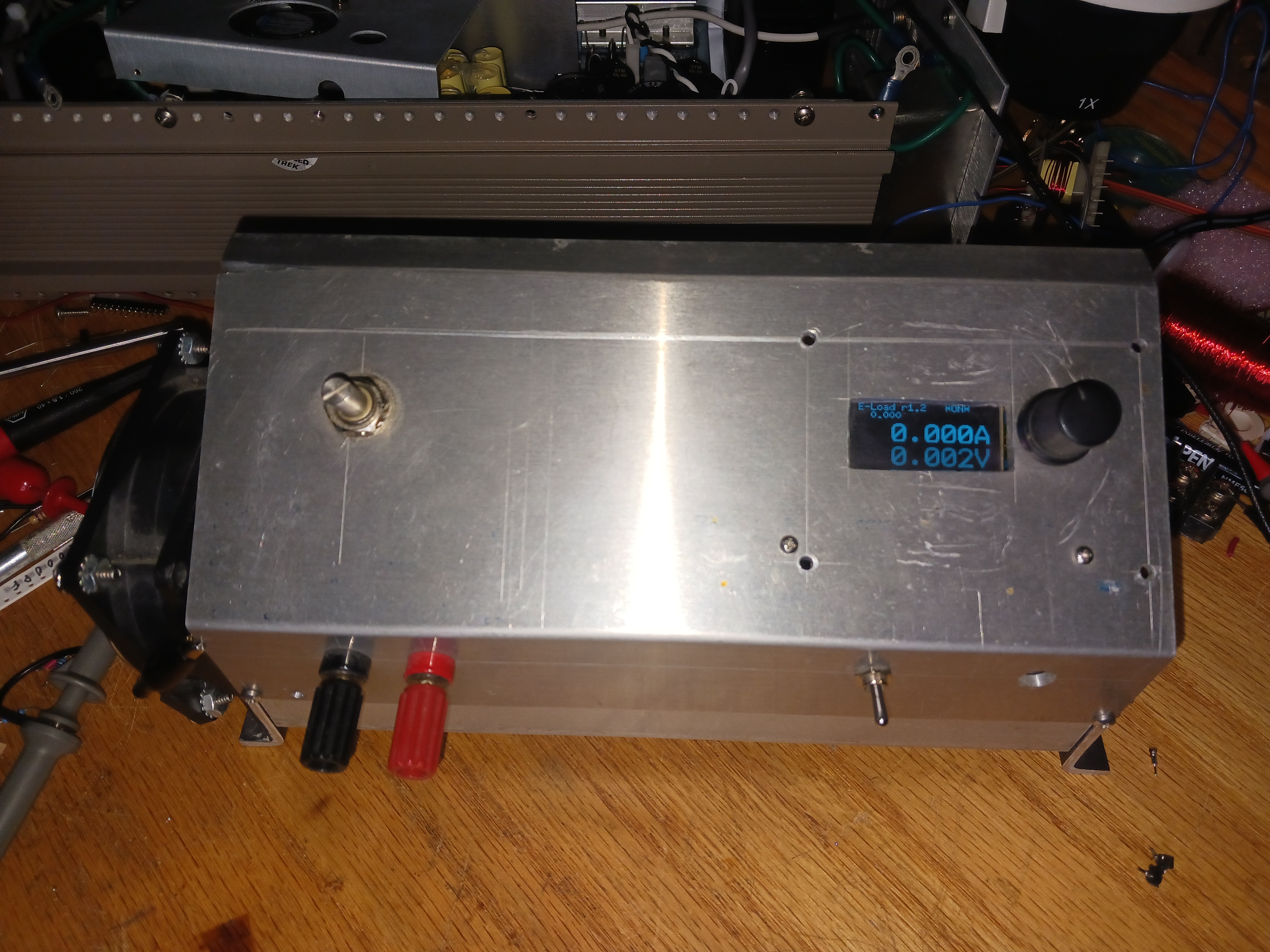

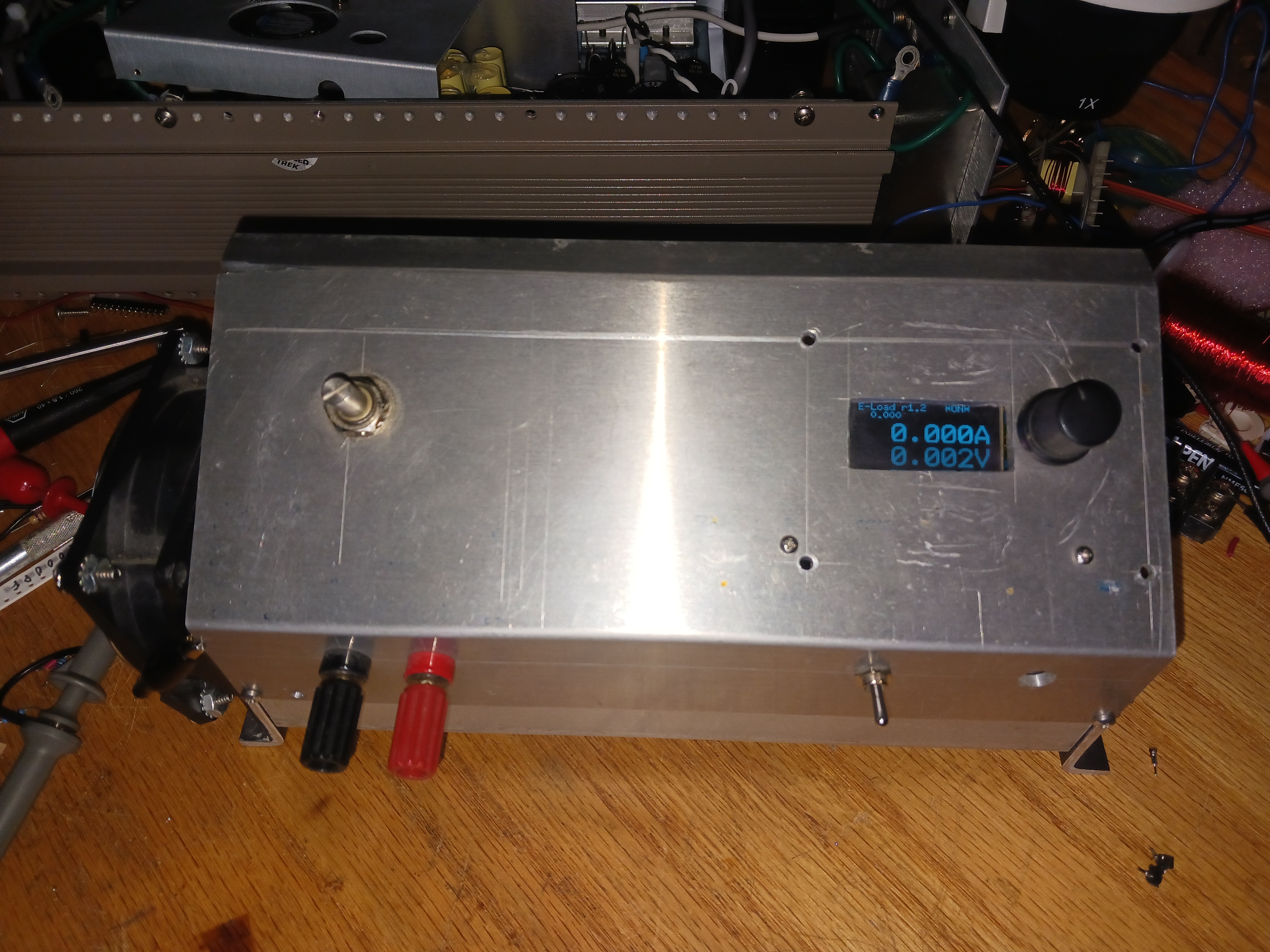

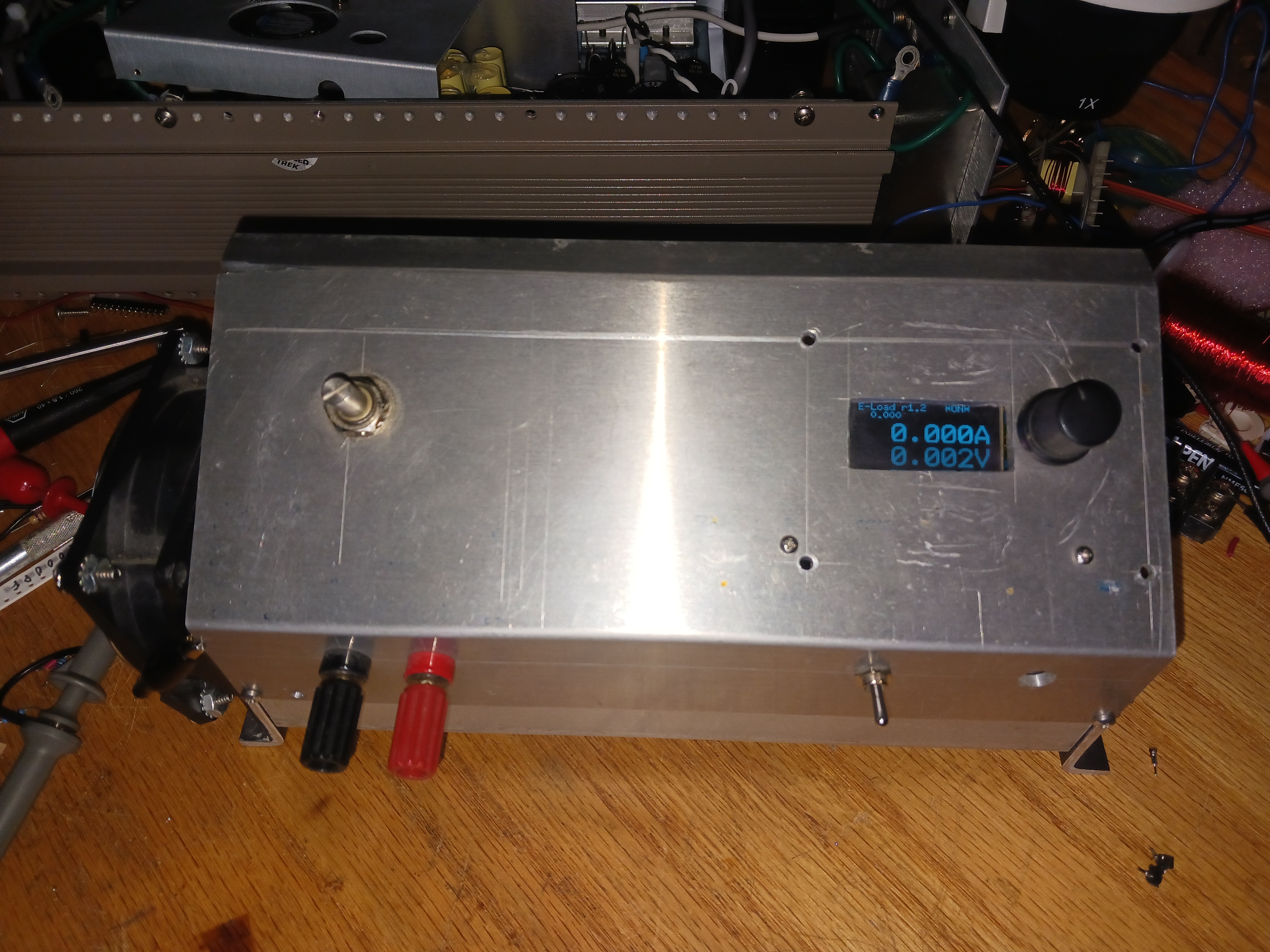

Rev 1: Digital set and display

Requiring an external DMM was inconvenient. And a voltage monitor is

also useful. Around that time, I designed LeoLed, with a 16b isolated ADC and 12 bit

DACs. It allows setting the output current precisely using an

encoder. The ADC has programmable ranges, so directly measuring the

0 to 0.5V shunt resistor was a good match. LeoLed has resistor

dividers on its inputs so directly measuring up to 100V was no

problem.

- LeoLed display

- Iset using encoder

- 15bit (16 bit bipolar) current monitor

- 0-100V voltage monitor

- Display of Iset, Imeasure, Vmeasure

- Increase current to 20A

- Increase voltage to 100V

- Separate 12V power supply input

- New slanted cover to accommodate display

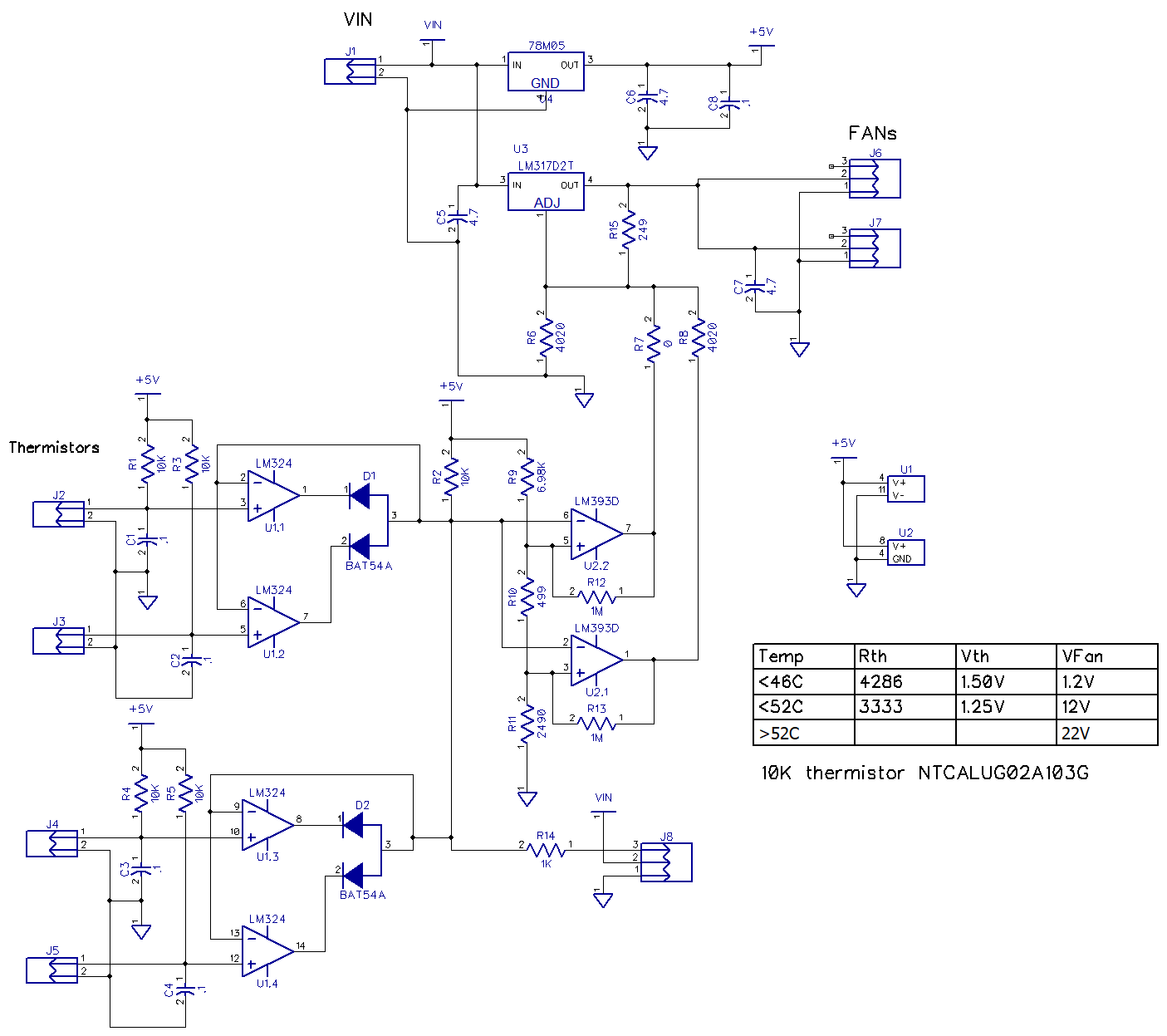

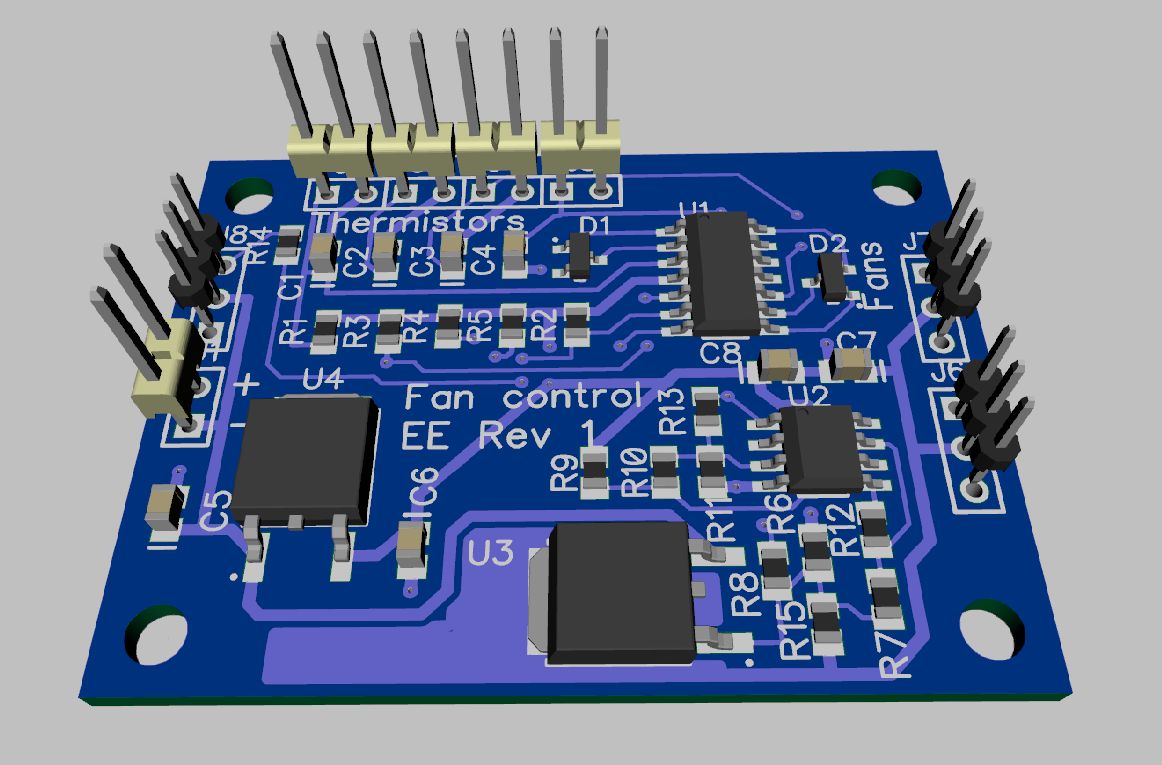

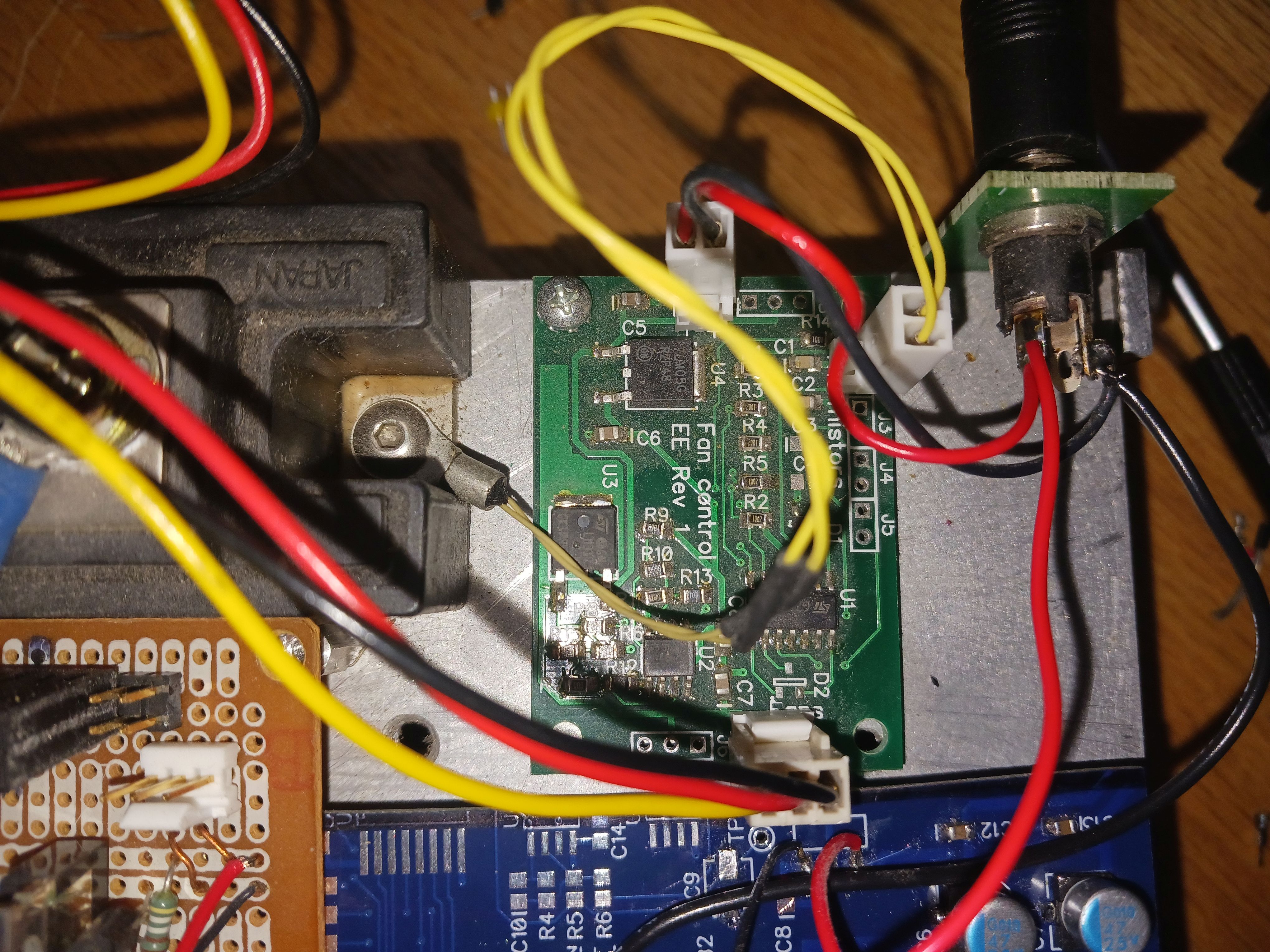

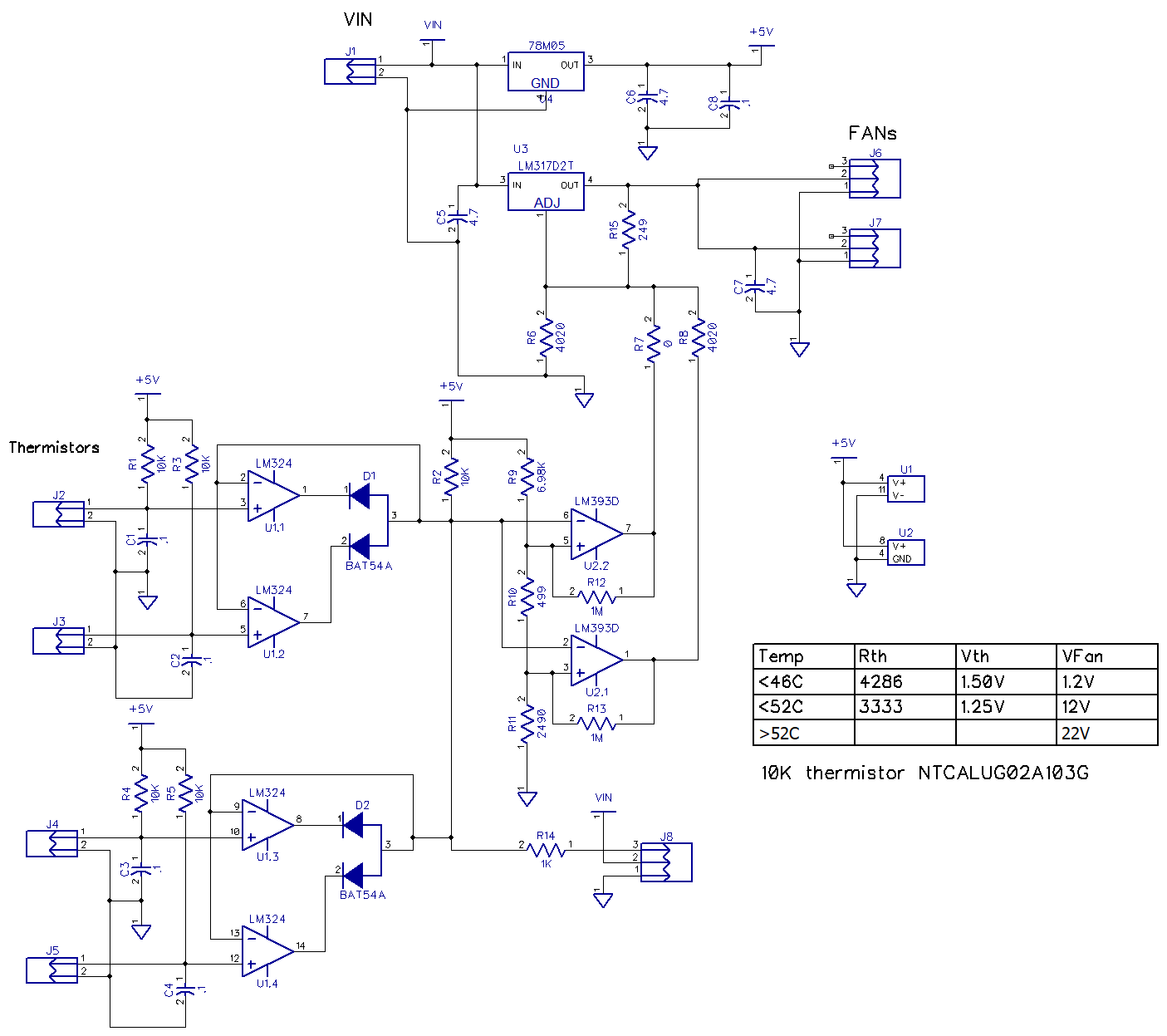

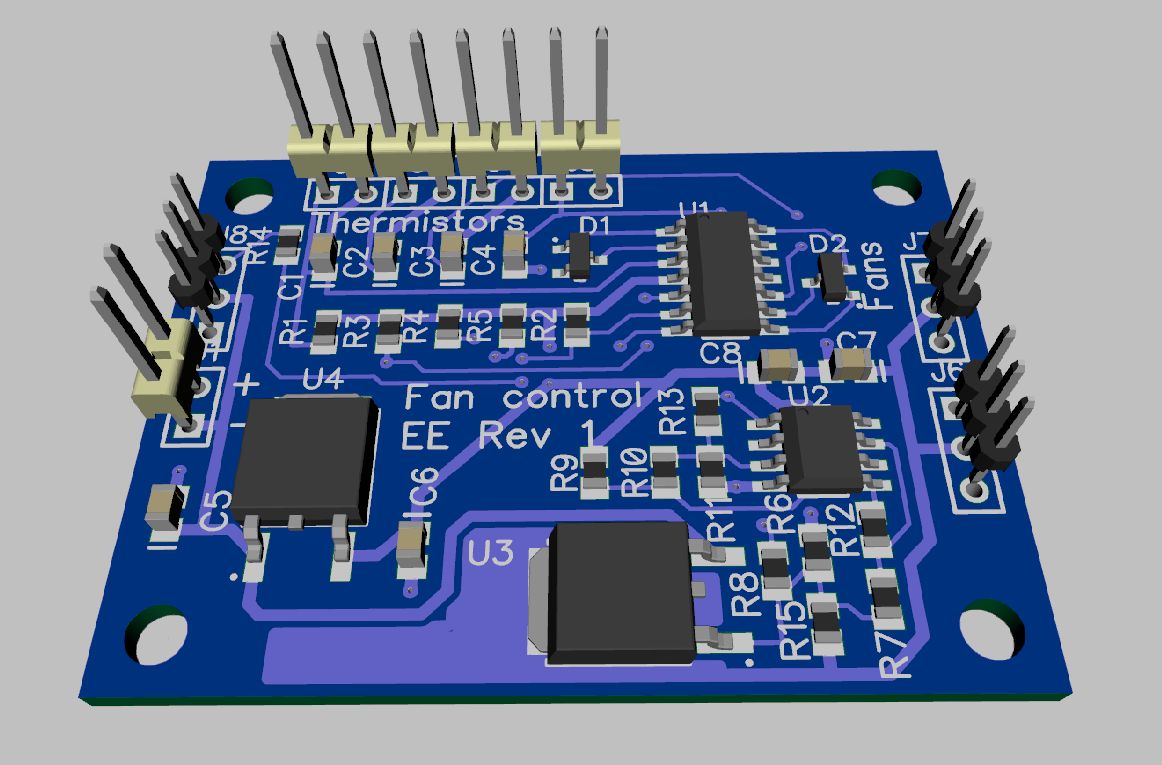

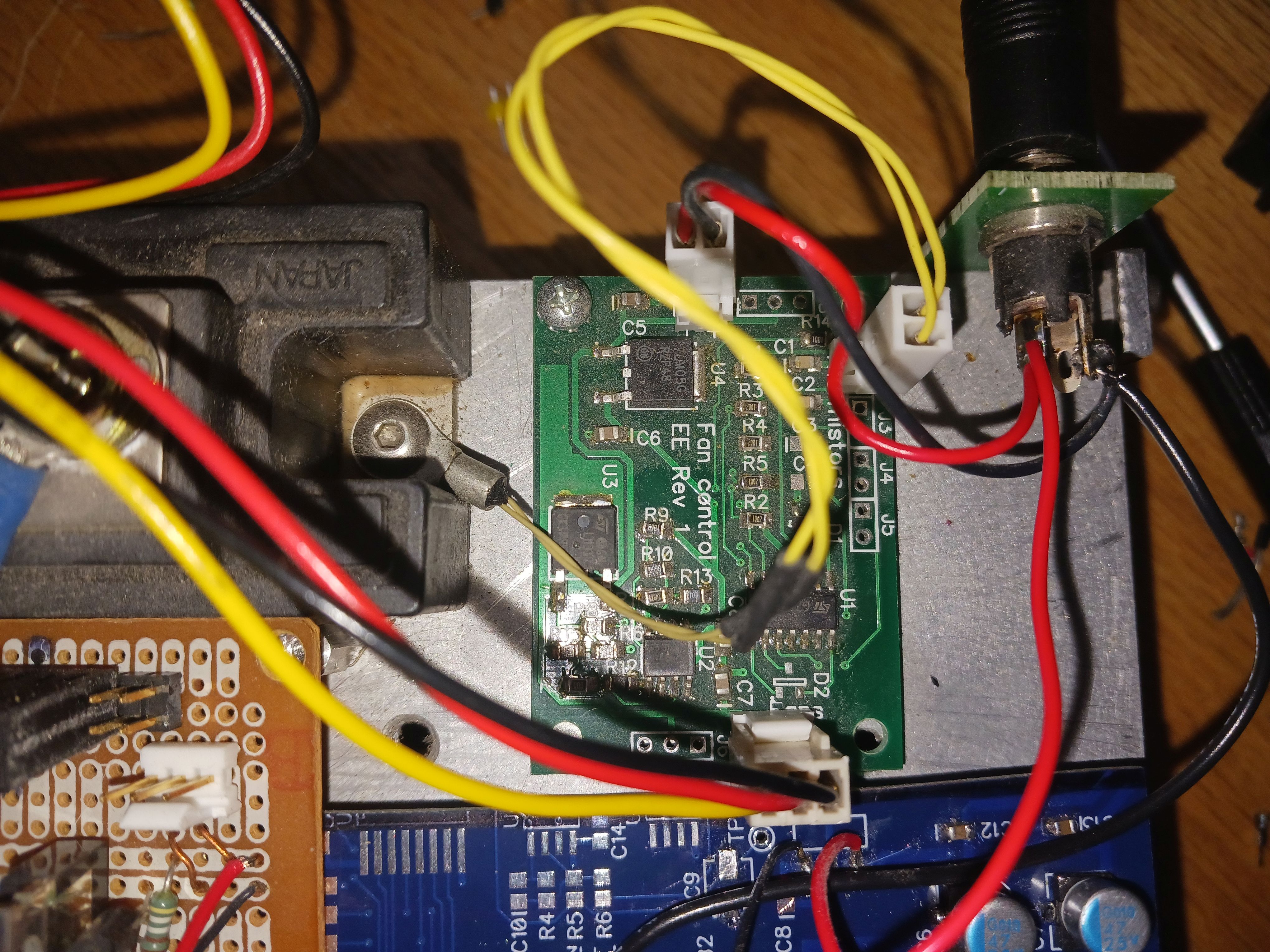

Rev 2: Variable fan control

Having the noisy fan always on is annoying. I designed a little Fan Control Board

that uses a thermistor to monitor heat sink and control the fan

speed. It has 2 fan speed settings plus OFF. It was designed for

PS--Load, but was equally applicable here. I wired the fan before

the power switch so the fan can remain on after the load is turned

off. There can be a lot of residual heat in the heat sink after the

load is removed.

Fan Board can monitor 1 to 4 thermistors and controls the fan based

on the hottest one. This circuit is for +24V input and fans. For 12V

input and fan, change R6 and R8. If you just need a single

thermistor, only use one thermistor connector and input R-C, and

U1.1, U1.2, R1, and D1 an be eliminated. J8 is if you want to

monitor the temperature.

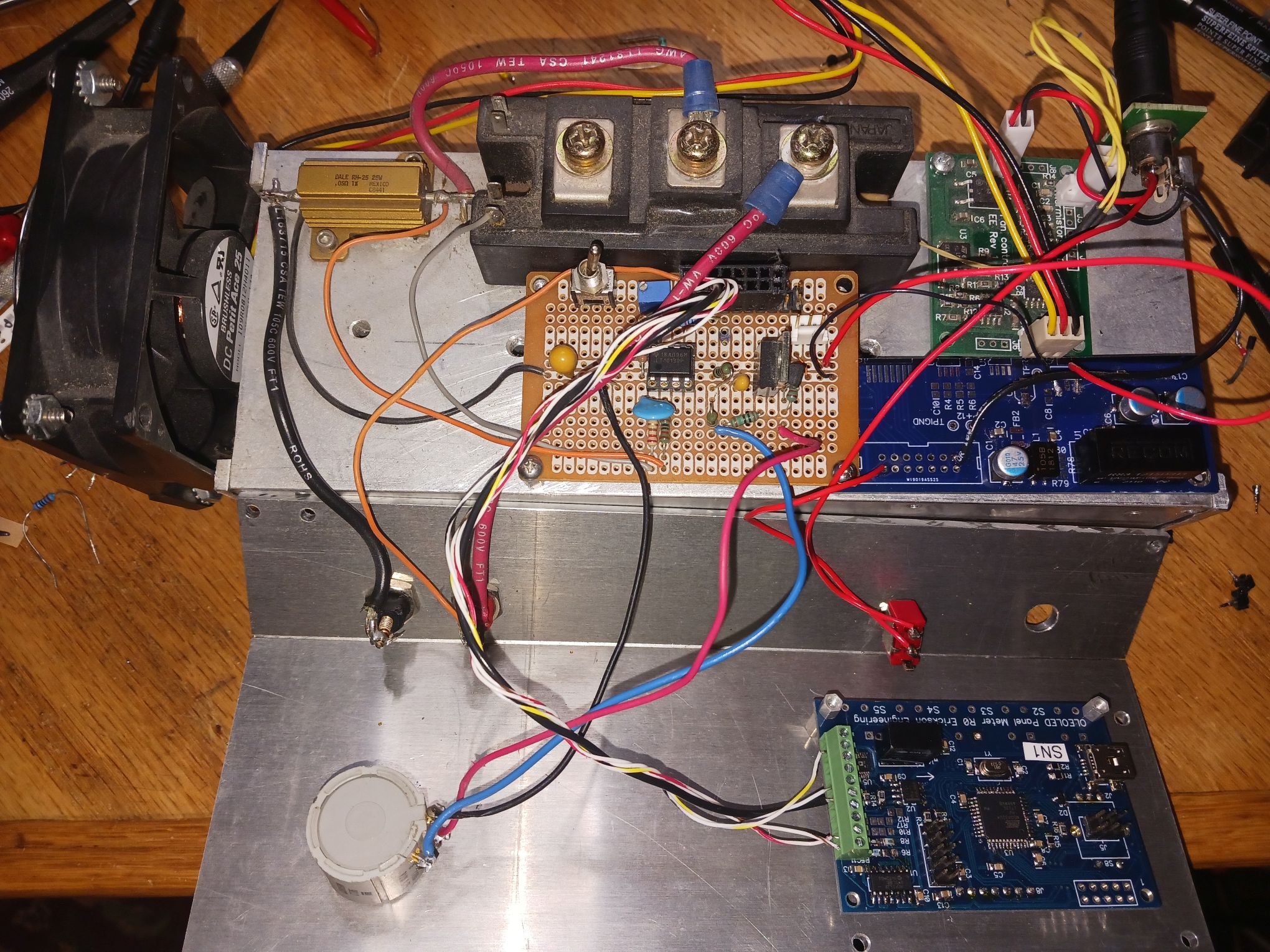

Rev 3: DC-DC

I had planned to isolate the +12V power to the load from ground, but

hadn't gotten around to it. Without isolation, you either had to be

careful about the source grounding, or be careful about the +12V

power supply grounding. An isolated 12V AC-DC (not 3 wire AC) could

be used. Neither is good. A proper isolated DC-DC is needed. The ADC

and DAC are already isolated on the LeoLed board. That's most of the

battle.

I've done work on DC-DC

common mode noise and finally settled on the 12V to 15V DC-DC

that I use on DIY-SMU. I had spare PC boards and could easily

band-saw off the small DC-DC power section. It's the thin blue board

on the heat sink.

It is not ideal, and generates a bit of 300KHz common-mode noise.

Still working on a final solution.

Rev 4: The Future?

E-Load works well and is meeting my needs for now, but clearly some

cleanup and improvements are in order. Maybe if I get not-busy. Then

again, it works the way it is.

Maybe just the firmware updates...

- Firmware improvements:

- Fine control of current. Needs more buttons or encoder

button.

- Maybe larger OLED board. See PS-Load for possibilities.

- SCPI control over USB

- Battery test mode

- Shutoff below voltage setting

- Accumulate Amp-hours

- Single PCB containing all ??

- Maybe a second PCB for front panel. OLED and switches.

- Maybe LeoLed 2

- A better cover, maybe 4 sided.

Back to Dave's Home Page

This page was last updated 10/21/23