Design

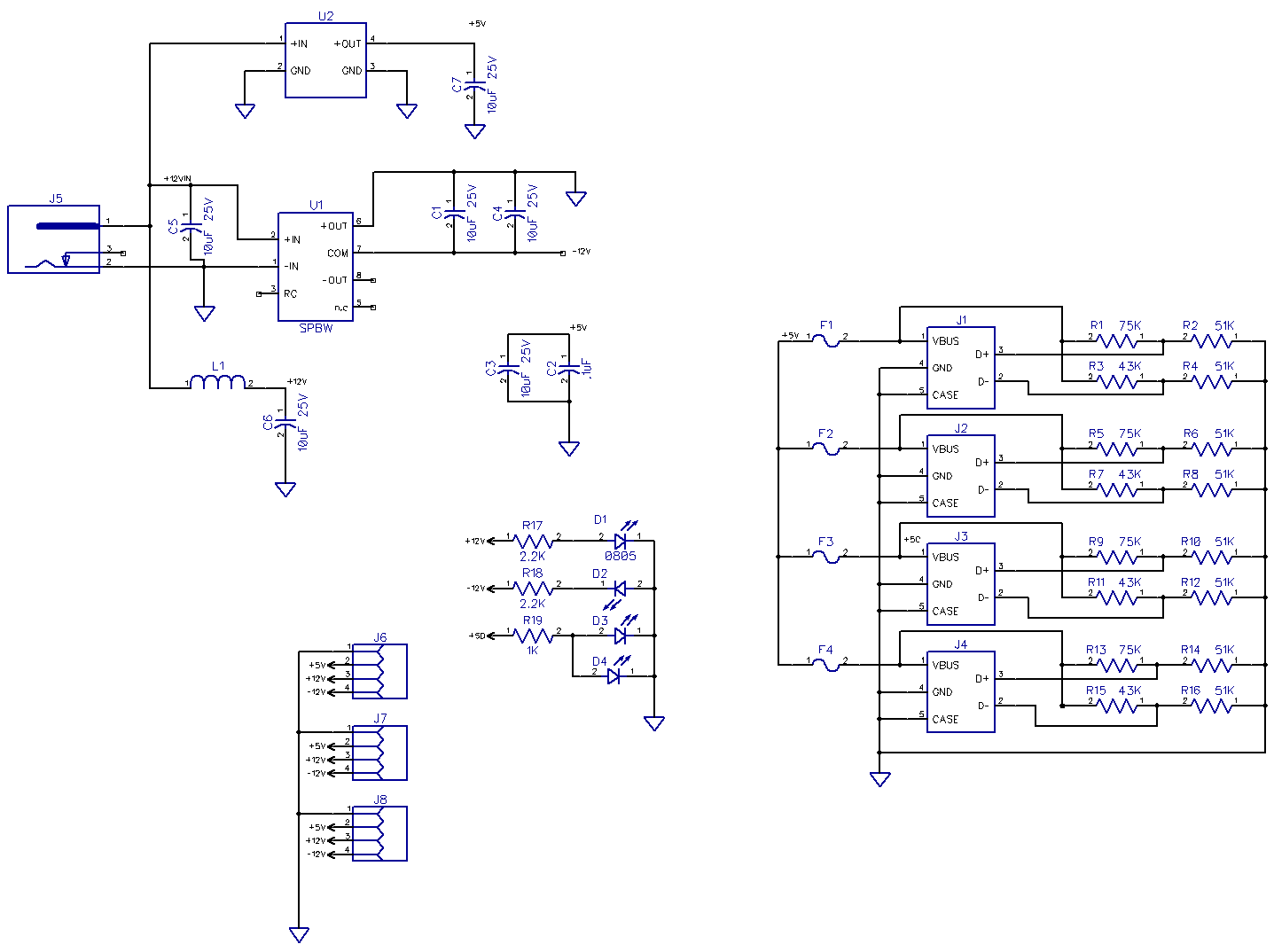

Yes I did use the cheapie Chinese buck

regulator for U2. I adjust them for +5.1V output and added input

and output ceramic (low ESR and ESL) capacitors. I use a 1A USB

circuit for the 5V,and fuse each USB device with a

self-resetting 2A fuse. For -12V I use a $7 12V to 12V DC-DC converter.

For +12V I just take the input +12V and distribute it to the four multi-voltage connectors.

For the +12V input I use a coaxial jack, 5.5x2.1mm, the most common one. Any +12V 3A to 5A power brick can power these. Or any 12V lighter plug cable. Make sure you use beefy 22AWG ore heavier cable. When I tried my 12V soldering iron with a 24AWG 6' cable on the boat, it not work. Heavier cable worked.

For the USB chargers, I found that most things work fine with no current programing resistors. But then I found that Apple i-things didn't like this and would not charge. I added two 150K pull-ups to D+ and D-, and that seemed to satisfy my wife's iPod touch on a docking speaker.

Then I tried an iPad Mini. It worked but took for-e-ver to charge. These want 1A or more. For 1A, different resistors are needed: 2.0V on D- and 2.8V on D+. See the schematic below. Rev1 had no resistors, I just soldered them to the USB connector pins on the back of the boards . Rev2 has the four resistors on each USB port.

J6-9 are 4 pin 3.81mm (0.15") pluggable screw terminals. These can easily be field wired, and then plugged or unplugged. When I need a standard 2.1mm or 2.5mm cable, I buy the cables (Digikey or Ebay) and build them up. Then label them for what they plug into. It is bad to plug a 12V cable into something that wants 5V.

When I run into a different size plug, I just cut the cord off the power supply and wire it into the correct pins.

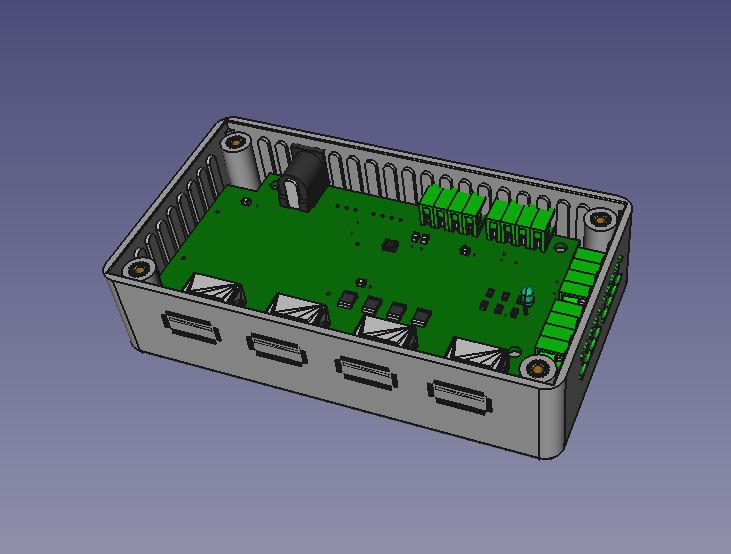

Here is 3D model of the board in a Hammond enclosure. Board 3D model was exported from Diptrace, then imported into FreeCad along with the Hammond enclosure mode. No buck regulator, too much work to build up a 3D model. I often find decent 3D models on grabcad, but couldn't find one for these boards.

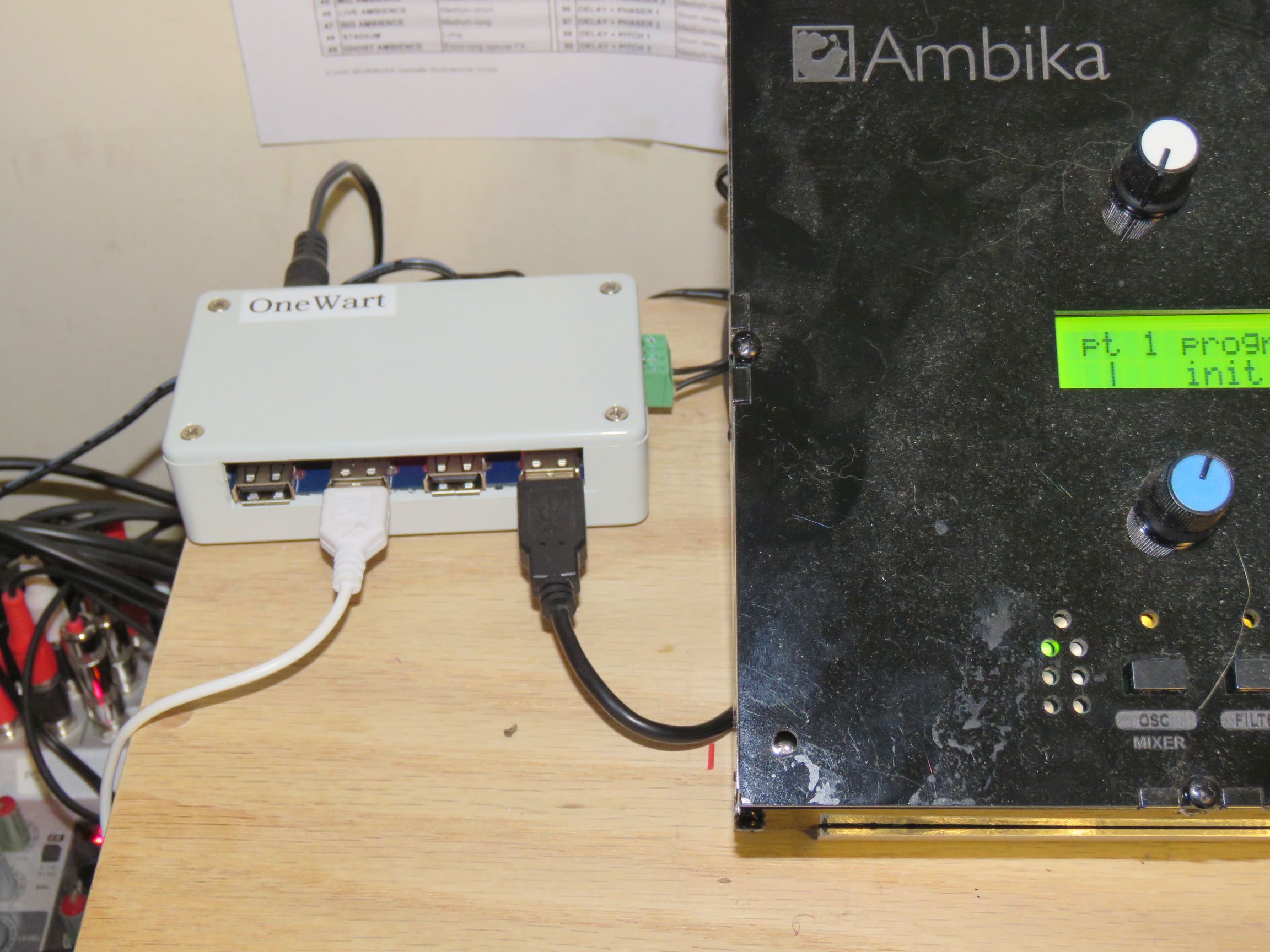

Here is a Rev1 OneWart mounted in a Hammond box with real parts. Cutting plastic slots for the connectors was more pain / work than expected. There are no good hand tools for cutting plastic. It is too thick to shear or cut with a knife, and too thin to saw or mill. I used a combination of a scoring knife for the horizontal cuts and band saw for the vertical cuts.

In a nice custom 3D printed box with one screw terminal connector plugged in. Thanks to Jimmy Su for designing and printing these.