DIY SMU:

Source Measure Unit Page 2: DIgital

The

Blog for this project

The

Schematics, PCB files, and BOM are here

Page 1: the Analog

part

Page 3: Board Bringup

The Schematics, PCB files, and BOM are

here

Page 3: Board Bringup

Page 4: Board Bringup II

YouTube

Video Chapter 1: DIY-SMU Intro

YouTube Chapter

2: New CPU and Case

YouTube

Chapter 3: New Case and CAD tools

YouTube Video 4: Instrument Control Via

SCPI

EEVBlog

Forum Page

The digital part of the SMU is fairly

straightforward. Compared to the older instruments based on older

processors, it is significantly smaller and lower cost.

ADC

The 5-6 digit ADCs on many commercial instruments

are often multi-slope designs typically using a discrete analog

front end and either a microprocessor or programmable logic for

the digital part. There are many ADCs

on the market. These perform well and are very small. Delta-Sigma

parts offer good performance as well as flexibility in trading off

accuracy vs speed. Most use an SPI interface which makes

isolation straightforward. Requirements:

- 24 bits, bipolar input, single ended

(pseudo-differential)

- ppm drift and non-linearity

- 4 wire SPI: CK, MISO, MOSI, SS/

- 2 or 3 channel Mux

- ~1KHz 20 bits performance, able to tradeoff

speed vs. bits

- 5V Vdd input range

- Human solder-able package

The AD7190/7193 parts look good. The AD7190 has 4

pseudo-diff inputs where the - input can be biased to the

reference voltage for bipolar operation. Perfect. Some more modern

parts are 3V only, but the '7190 can be either. To use a 5V

or 3V part, the input will probably need to be buffered by a

precision, low-voltage RRIO op-amp such as the TLC2272.

DAC

The original 236 used two 14b DACs, with external

serial to parallel registers, and current to voltage amplifiers.

Lots of giant DIP parts. I plan to use a single tiny 16b 4-channel

DAC with low INL errors. It too is SPI.

Main Processor

The processor requirements are

straightforward.

- ~256K bytes Flash (program) memory

- 128K RAM

- USB Device interface

- Serial emulation for instrument control

- Used for device programming and debug

- EEPROM for calibration factor storage

- SD Card would be nice, but not absolutely

needed.

- High-resolution color display

- Used for setup, numeric and graph

display.

- SPI

- Touch screen would be nice

- Leaning towards 480 x 320 landscape TFT

with touch screen

- Need high level graphics library.

LittleGL?

- Looking at Nextion smart displays.

- Controls:

- Buttons for major modes:

- Encoder for menu and selection

- Encoder to set values:

- Digit selection buttons: <, >

- Encoder button

- SPI Interface for Instrument

- Isolated on the instrument board

- 3-4 select lines: ADC, DAC, GPIO

- Compliance input

- +12V input voltage

- Regulators for +5V, +3.3V

- +5V and +12V to the analog board.

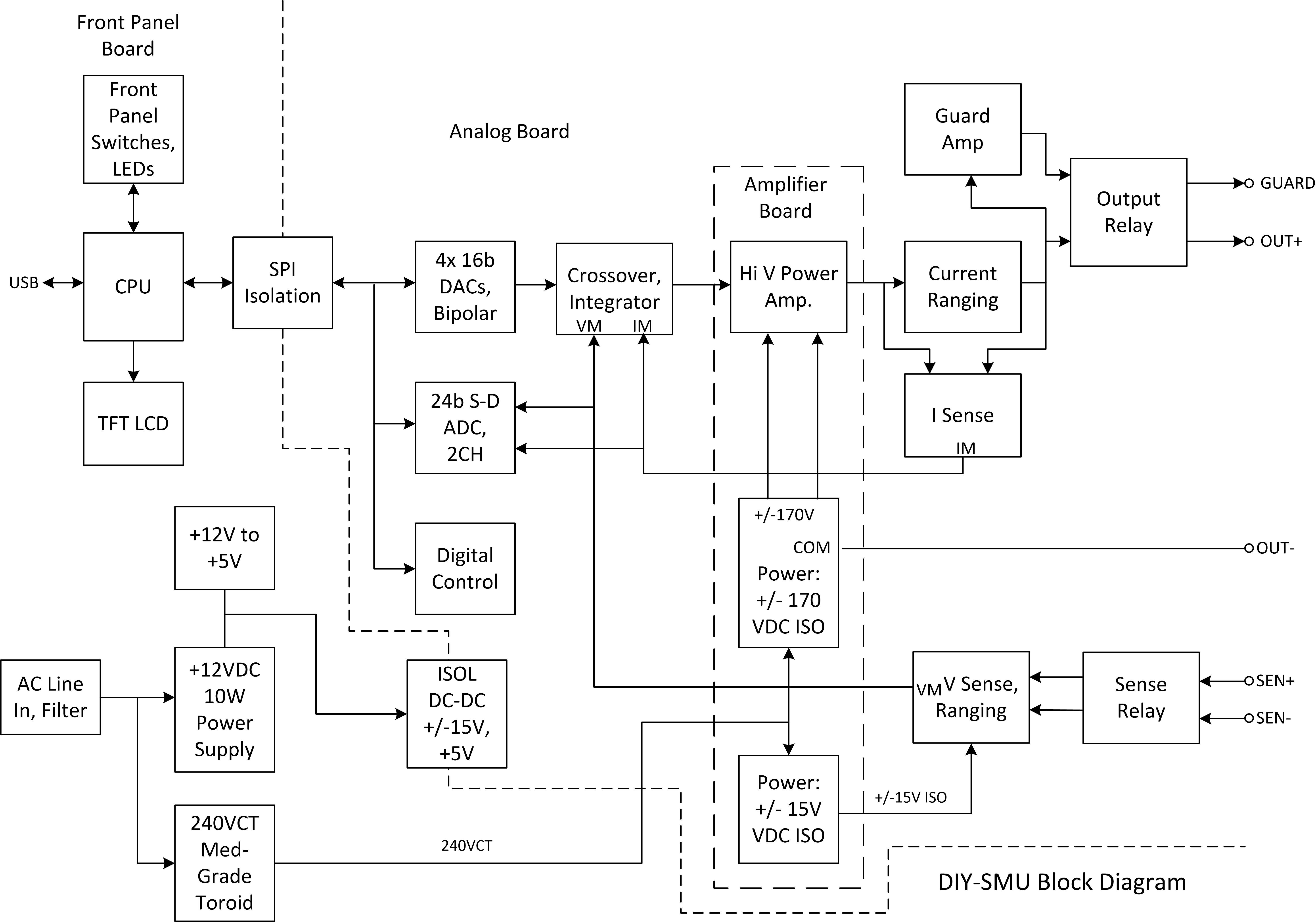

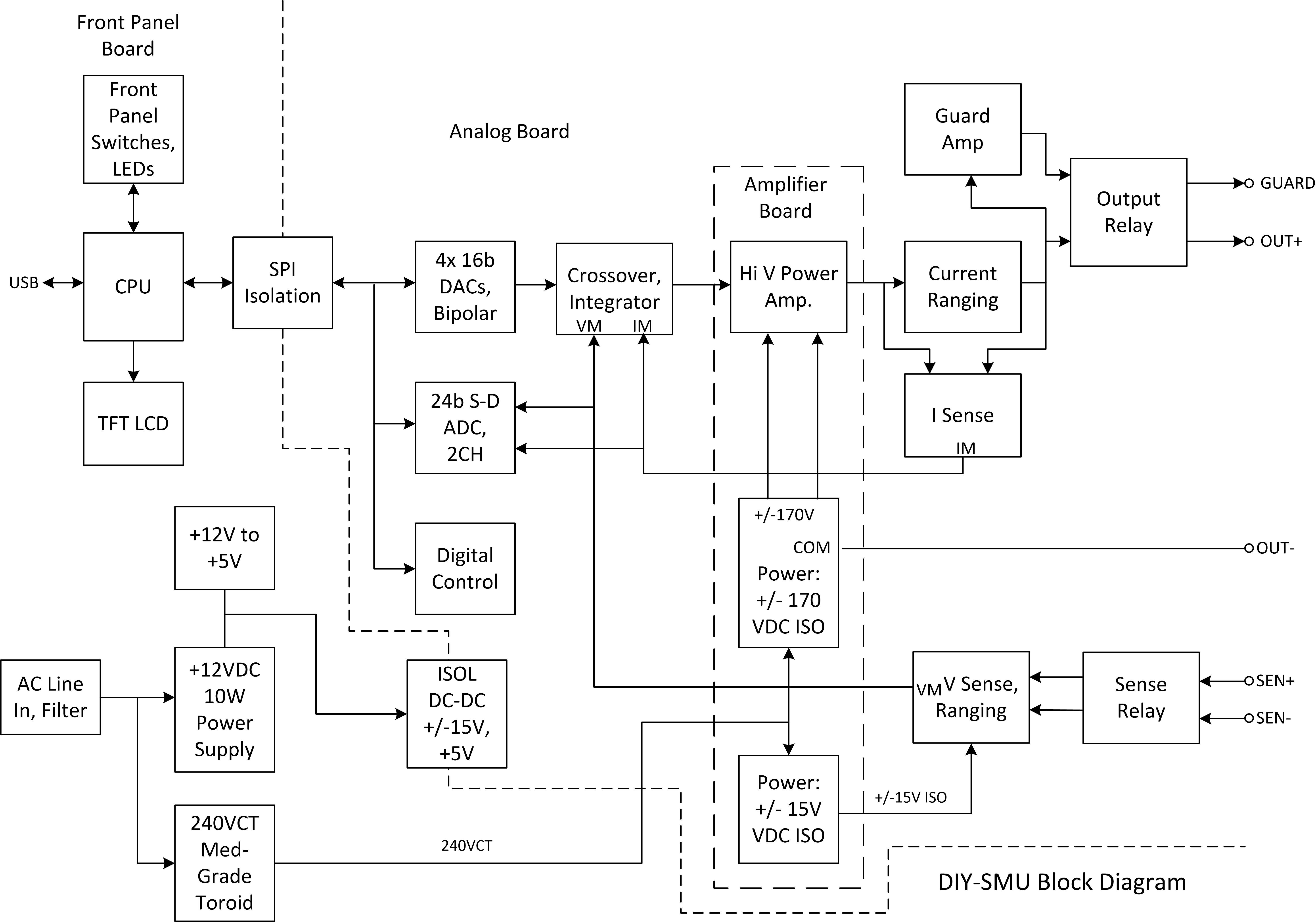

Here is the block diagram for the system. The

digital parts are on the left.

I am a fan of Teensy processors having used them on several

project. The processing, I/O speed, and I/O needs for this project

are not much. The ADC operates at a maximum of about 4KS or 250uS.

The LCD has the highest demands to keep up with user inputs and

perform real-time data display. A 480x320x16b display has

307KB of display memory. A single Teensy 3.x or 4.x should

do the job.

Since a front panel board with LCD and controls is needed and

these use most of the I/O, the processor module should probably be

mounted to the back of this board. A single 14-pin ribbon cable

can provide SPI and power to he analog board. An internal USB

cable can connect the Teensy Micro B to a rear panel USB-B

connector.

For the initial bring-up, I'll use one of my LeoLed controllers. This is an

Arduino Leonardo 8 bit processor with a small OLED display, an

encoder, and a few buttons.

Nice Buttons

Having nice buttons with labels is a challenge

for DIY projects. I haven't figured out how to make them. Hmmmm.

GUI Software

- Main screen

- Modes, Ranges

- I and V force and measure readings

- Encoder to set values

- Plot Screen

- Time plots of Measure data

- Button and encoders for X,Y offset and

gain

- X/Y measure vs. force plots

Page

1: the Analog part

Page 3: Board Bringup

Dave's

Home Page

Last Updated:

10/14/2022